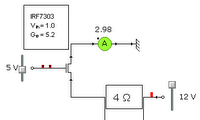

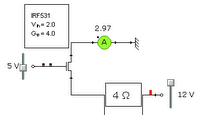

Crocodile Clips only has two configurable parameters for a n-channel MOSFET: the gain factor and the threshold voltage. Since the other voltages (i.e. drain-source, gate-source, etc.) and parameters are not configurable for the sake of simulations, I'll guess that the voltage and current specs are limits for the sake of breakdown and focus on gain and threshold until I learn more. None of the data sheets that I have looked at speak of a 'gain factor', but I read that forward transconductance what Croc Clips means by gain factor.

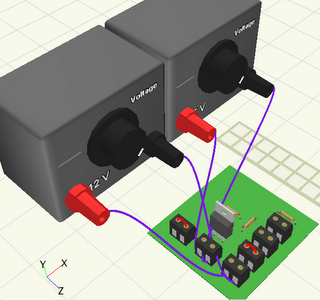

In the pictures above, I have changed the MOSFET parameters in Croc Clips to use the threshold voltage and gain factor from the data sheets for the IRF7101, IRF7303, and IRF531. The IRF7101 is used in the

Roctronics circuits, so I'm using that as a baseline in the simulations. The IRF7303 is more readily available now, so we're considering it in our schematics for our implementation of the Roctronics boards. The IRF531 is available locally and in the nice TO-220 package that make bread-boarding easy. In short, it appears that our requirements are basic enough that we can use any of the MOSFETs we are looking at.

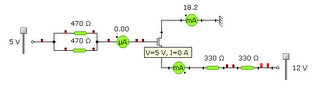

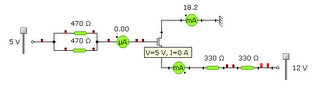

In my previous post, I wonder about the resistance from gate to source... heh, I now have a better understanding of the 'field-effect' part of MOSFET (and I already know that the MOS part is obsolete). There is 'practically no input current' on the gate - you can see in this simulation that Croc Clips assumes none:

So for the most part, when we pass the voltage threshold on the gate, the MOSFET turns on. Below are some rules that I picked up on a Web site talking about the scaling effects of MOSFETs - I may have interpretted the gain part of the equations incorrectly. Even if these aren't completely accurate - they appear to be pretty decent guides based on my playing with the Crocodile Clips.

drain-source current:

cutoff: 0 when Vg < Vt (i.e. 3.8 < 4)

linear: GainFactor * ((Vg - Vt) Vd - (Vd^2 / 2)) when 0 < Vd < Vg - Vt

saturation: (GainFactor / 2) * (Vg - Vt)^2 when 0 < Vg - Vt < Vd