I first heard about the Astronaut Farmer while looking at the CP Technologies Web site (my quest for ideas on small-scale strap-on booster designs). There was a lot of information there about the movie and skimming the info, I decided that I'd like to go to the movies on Feb 23 (opening night). It worked out that I was able to go a screening of the show today - great movie, in my opinion.

There was a point in the movie where there is a failure and I was horrified: I thought that the BATFE had worked with the Polish Brothers to help the public see the 'light' on their current case affecting rocket propellant and ignitors used by hobbyists. In the movie, it is the FBI rather than the BATFE, but a similar idea (Farmer was fine building his rocket - it was when he attempted to buy fuel that he got into trouble - even though he had attempted to follow known regulations).

There is a lot of family focus in the movie - the kind that I like because it helps me consider my role as a parent and gives me some things to think over. Some details are ignored - again, a nice thing - for example, Farmer allows the public to come into his garage and see the rocket and the line goes on for miles (apparently, these were only the most well behaved humans on the planet because there was no mess and no fights). I believe that the movie was filmed in New Mexico - I only mention it because the house, the ranch, etc. were so pretty that they really complimented the story / experience.

Good stuff.

Tuesday, January 30, 2007

Monday, January 29, 2007

Feb launch scrubbed but...

I'm not too down: on Monday, January 29th, I'll be attending a screening of The Astronaut Farmer and when we do get to launch, I'll be attempting my L1 cert on my second flight of the Bullet. I've been assisting with some PHP on the club Web site and one of the members showed me the casing and motor I'll be using for my L1 :) I'll have to pay for the H73 motor, but I'll be able to borrow the casing.

Friday, January 19, 2007

building a few cluster models

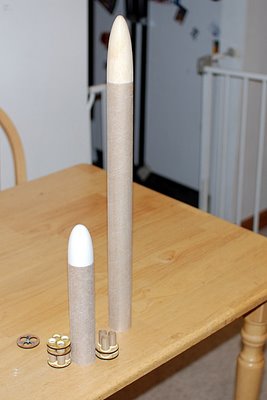

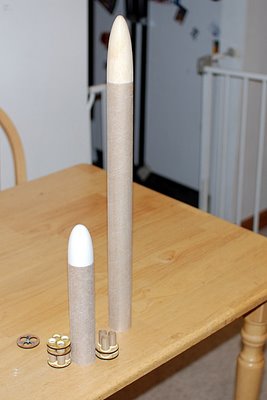

We have a rocket day coming in the next month or two at church, so I'm building a couple models size rockets for launching there. These are my first venture into clusters - and they are tiny clusters. The tall rocket is a Rhino and the shorter one is a Baby Bertha.

Both rockets use BT-60 size tubes, so I picked up a couple cluster mounts from a local rocket guy. The Baby Bertha will use 3 tiny A motors and the Rhino will use 4; this will give the Baby Bertha about 6.6 N-s and the Rhino 8.8 N-s of total impulse (equivalent of mid-C).

Both rockets use BT-60 size tubes, so I picked up a couple cluster mounts from a local rocket guy. The Baby Bertha will use 3 tiny A motors and the Rhino will use 4; this will give the Baby Bertha about 6.6 N-s and the Rhino 8.8 N-s of total impulse (equivalent of mid-C).

Wednesday, January 03, 2007

Jan 6 launch scrubbed

Disappointing :(

- from http://www.ncrocketry.org/

Regrettably but sensibly, NCR will NOT attempt to launch on Saturday the 6th. Our equipment trailer remains buried in deep snowdrifts and is pretty much in-accessible, as is the Atlas Site.

Tuesday, December 26, 2006

preparing for first Bullet flight

Still have some finishing work to do on the Bullet, but it is nearly ready for its first flight. I'm planning on flying a couple flights on Jan 6 at the Northern Colorado Rocketry launch.

In this picture, the base kit has had an avionics bay and an extension added. The avionics bay will carry the electonics that Michael and I have been working on. The extension is simply there to connect the avionics to the nose cone, but the additional length helps the rocket fly stably with heavy tail.

One last bit (besides the finishing of the rocket) is to test fire a motor. I'll be using a reloadable motor system and I need to verify that I can safely assemble and fire the engines without it blowing up or failing to fire the ejection :)

In this picture, the base kit has had an avionics bay and an extension added. The avionics bay will carry the electonics that Michael and I have been working on. The extension is simply there to connect the avionics to the nose cone, but the additional length helps the rocket fly stably with heavy tail.

One last bit (besides the finishing of the rocket) is to test fire a motor. I'll be using a reloadable motor system and I need to verify that I can safely assemble and fire the engines without it blowing up or failing to fire the ejection :)

Thursday, December 21, 2006

some individuals weights

I've been wondering how much my quick links weigh and other individual parts. I finally got around to weighing the stuff this evening:

It's kinda funny that I differentiate between 1/2 and 1/3 because my scale isn't that precise, but that's the way I read it.

- 1200 lbs quick link - almost exactly 1 oz

- 800 lbs quick link - about 1/2 oz

- 660 lbs quick link - about 1/3 oz

- 16 ft kevlar - about 3/4 oz

It's kinda funny that I differentiate between 1/2 and 1/3 because my scale isn't that precise, but that's the way I read it.

Saturday, December 16, 2006

device direction

We're trying to make a decision on the device that we want to commit to. We've been bouncing between the PIC and the AVR for a while and feel that we need to pick one to focus on. In my initial research, it seems like the AVR and PIC are pretty much equivalent competing products. I have seen some vague references (i.e. both device families have similar features as well as unique features so the process of choosing one can be daunting) to differences in the families, but nothing helpful or specific yet.

Michael has gathered some great links. We'll likely consider where we want to be in the longer term (guidance) and see if one of the product families fit better than the other.

Michael has gathered some great links. We'll likely consider where we want to be in the longer term (guidance) and see if one of the product families fit better than the other.

Wednesday, December 13, 2006

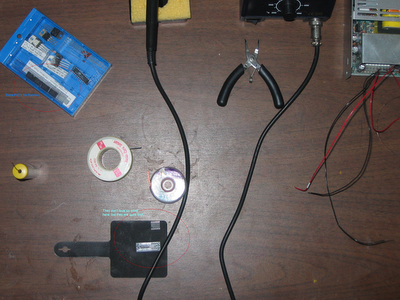

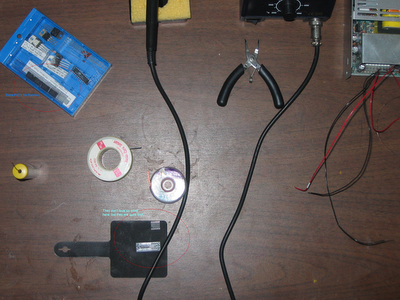

testing R/C with an igniter

I hooked everything up expecting to be disappointed. I thought that it was all good in theory, but it surely wouldn't work in practice. Making a hot fire would surely be more difficult that turning on an LED.

In the first attempt, I took the pictures and I am all sorts of no good at taking pictures. Shanelle assisted in the second attempt by taking some excellent pictures. I hooked everything up and told Shanelle what to expect and then flipped the switch.

It takes about 3 seconds for the igniter to get hot enough to fire. I'm just using a 6 cell AA pack of NiMH batteries. The total voltage is 8.4 volts - quite a bit lower than the preferred 12 volts. It's nice that the igniters were willing to give me joy on the 8.4.

In the first attempt, I took the pictures and I am all sorts of no good at taking pictures. Shanelle assisted in the second attempt by taking some excellent pictures. I hooked everything up and told Shanelle what to expect and then flipped the switch.

It takes about 3 seconds for the igniter to get hot enough to fire. I'm just using a 6 cell AA pack of NiMH batteries. The total voltage is 8.4 volts - quite a bit lower than the preferred 12 volts. It's nice that the igniters were willing to give me joy on the 8.4.

Tuesday, December 12, 2006

another post about the R/C backup circuit

I tested the R/C circuit with a few different types of capacitors and 4013s. Actually, the 4013 that I had been using was SGS and tonight I tested with a Motorola one. Of course, one expects them to work the same, but I needed to try it to make sure. The yellow capacitor that is in the circuit is one that I picked up last week: a fancy poly cap that isn't truely a precision capacitor, but it is rated at +/- 1%. The black boxy one sitting next to the bread board is +/- 10%. The green one is the one I have been using and is also +/- 10%.

The difference between the two images above is the position of the gimble. Turning the LED on when using the 1% capacitor takes 1 click at the center of the throw. When I use the black box capacitor, it takes 2 clicks about 2/3 up in the throw. When using the green capacitor, it takes 2 clicks at the center. After 1 click from off, the lower precision capacitors flicker. Of course, in real action, I'll use the switch (top left of the controller), but the gimble adjustment seems like a good test to see where the circuit is sensitive.

I feel good about the reliability of the circuit and parts availability, so it is time to solder a version together and test the first circuit with some higher current. The yellow capacitors are expensive at 30 cents each, but not prohibitively expensive - I think that I'll start with those and I'll use the Motorola 4013 since I have more of those than the SGS. The firing mechanism is currently using an IRF 531, which are locally available, so I'll be putting that into the initial prototype.

The difference between the two images above is the position of the gimble. Turning the LED on when using the 1% capacitor takes 1 click at the center of the throw. When I use the black box capacitor, it takes 2 clicks about 2/3 up in the throw. When using the green capacitor, it takes 2 clicks at the center. After 1 click from off, the lower precision capacitors flicker. Of course, in real action, I'll use the switch (top left of the controller), but the gimble adjustment seems like a good test to see where the circuit is sensitive.

I feel good about the reliability of the circuit and parts availability, so it is time to solder a version together and test the first circuit with some higher current. The yellow capacitors are expensive at 30 cents each, but not prohibitively expensive - I think that I'll start with those and I'll use the Motorola 4013 since I have more of those than the SGS. The firing mechanism is currently using an IRF 531, which are locally available, so I'll be putting that into the initial prototype.

Saturday, December 09, 2006

all power

This car is all power. In fact, before Isaac installed the house, he decided it was too much power for his lego man. He installed a man with a helmet and we had to brainstorm to come up with a seat belt before taking any more drives!

Note that this was taken with the boys' camera... it isn't a Canon / Nikon thing.

Note that this was taken with the boys' camera... it isn't a Canon / Nikon thing.

Thursday, December 07, 2006

XM Radio Constellation

I was curious to find out how big the XM Radio constellation is because I was so impressed with our reception on our Thanksgiving trip to the mountains. On our way back from the cabin we rented, we took some roads that were in between mountains and deep in the trees and we never lost reception.

Well, the XM Radio wikipedia entry has lots of great info, but it wasn't immediately obvious how big their constellation is or current orbits. While searching around, I bumped into the decode systems page which led me to VITA.

I know nothing about VITA - perhaps they are scum; however, the interesting bit to me is that there is a group of volunteers that have a license for a satellite constellation. Interesting. Serendipity do day.

Well, the XM Radio wikipedia entry has lots of great info, but it wasn't immediately obvious how big their constellation is or current orbits. While searching around, I bumped into the decode systems page which led me to VITA.

I know nothing about VITA - perhaps they are scum; however, the interesting bit to me is that there is a group of volunteers that have a license for a satellite constellation. Interesting. Serendipity do day.

great capacitor resources

I'm struggling to grok all that capacitors are and do. Here are a couple resources that I assume that I'll keep coming back to. Capacitor Concepts has a nice graph about types of capacitors, what they are used for, and related equations for the different types and uses. This site details the meanings of various capacitor markings - important for me because I have accumulated a bunch of capacitors and very few say helpful things like 10uF 50VDC; most of my capacitors say things like 0.1k or 103M.

R/C Backup Recovery

This great (old) article by Ron Hewitt shows a simple circuit to capture an R/C signal. I built the circuit as-is with parts that I happened to have and the Michael and I modified it to fit recovery needs.

I attempted to build this similar circuit, but didn't have all the parts necessary. I got some variance where the transistor would be when I moved the gimble, but I wasn't able to complete the circuit to drive a MOSFET or anything. I like the 4013 circuit because it worked first time and is now my circuit.

This excellent page gave us a lot of good information about the way the receiver is communicating with the servos. I would have liked to build the circuit they use, but the local electronics store was out of both the 74HC123 and 74HC74! It isn't worth $5 in shipping to get $1.28 in parts, so I think I'll put off building this one until some other time.

I attempted to build this similar circuit, but didn't have all the parts necessary. I got some variance where the transistor would be when I moved the gimble, but I wasn't able to complete the circuit to drive a MOSFET or anything. I like the 4013 circuit because it worked first time and is now my circuit.

This excellent page gave us a lot of good information about the way the receiver is communicating with the servos. I would have liked to build the circuit they use, but the local electronics store was out of both the 74HC123 and 74HC74! It isn't worth $5 in shipping to get $1.28 in parts, so I think I'll put off building this one until some other time.

Monday, December 04, 2006

nanotubes to diamonds

I always knew that diamonds were carbon, graphite was carbon, etc. but I have never heard it put this way:

Diamonds are three-dimensional crystals of pure carbon. Two-dimensional carbon is graphite, while nanotubes are considered a one-dimensional form of pure carbon. (Technically, graphite and nanotubes have three dimensions, but the Z axis on graphite and the Z,Y axes on nanotubes are so small that they become irrelevant.)- from a news.com article

Saturday, December 02, 2006

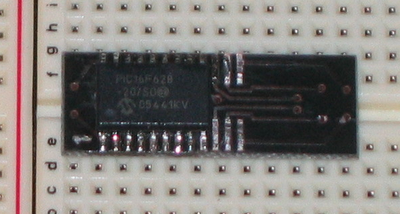

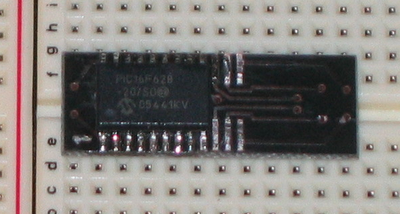

my first SMD solder attempt

I had intended to use the toaster oven or electric skillet for doing surface mount, but I found out today that the required solder paste is hard to get and mighty expensive. I had to revert to doing it by hand.

My strategy was to tack the chip down on pins 1 and 18. That turned out to be more difficult than I had anticipated: when I'd get the solder soft to move the chip for alignment, I'd repeatedly move it too far. I finally got it aligned and then soldered all pins in a rough fashion - just making sure I got a good bead on each lead and it flowed under the PIC leads. After everything had some solder on it, I used a fine desolder braid briefly on each lead to pull up the bridges.

After everything was soldered, I tested by poking each pin to see if it moved. None did. Then I put the PIC / adaptr into the bread-board to check resistance. I had an initial scare when I hit Vcc, but then I realized that would probably be okay. I'm looking forward to trying out a circuit now.

My strategy was to tack the chip down on pins 1 and 18. That turned out to be more difficult than I had anticipated: when I'd get the solder soft to move the chip for alignment, I'd repeatedly move it too far. I finally got it aligned and then soldered all pins in a rough fashion - just making sure I got a good bead on each lead and it flowed under the PIC leads. After everything had some solder on it, I used a fine desolder braid briefly on each lead to pull up the bridges.

After everything was soldered, I tested by poking each pin to see if it moved. None did. Then I put the PIC / adaptr into the bread-board to check resistance. I had an initial scare when I hit Vcc, but then I realized that would probably be okay. I'm looking forward to trying out a circuit now.

Thursday, November 30, 2006

learning about MOSFETS and gain

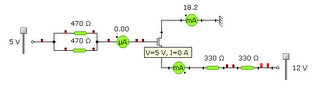

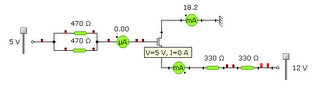

Crocodile Clips only has two configurable parameters for a n-channel MOSFET: the gain factor and the threshold voltage. Since the other voltages (i.e. drain-source, gate-source, etc.) and parameters are not configurable for the sake of simulations, I'll guess that the voltage and current specs are limits for the sake of breakdown and focus on gain and threshold until I learn more. None of the data sheets that I have looked at speak of a 'gain factor', but I read that forward transconductance what Croc Clips means by gain factor.

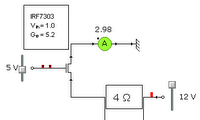

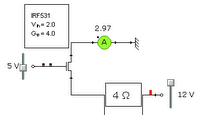

In the pictures above, I have changed the MOSFET parameters in Croc Clips to use the threshold voltage and gain factor from the data sheets for the IRF7101, IRF7303, and IRF531. The IRF7101 is used in the Roctronics circuits, so I'm using that as a baseline in the simulations. The IRF7303 is more readily available now, so we're considering it in our schematics for our implementation of the Roctronics boards. The IRF531 is available locally and in the nice TO-220 package that make bread-boarding easy. In short, it appears that our requirements are basic enough that we can use any of the MOSFETs we are looking at.

In my previous post, I wonder about the resistance from gate to source... heh, I now have a better understanding of the 'field-effect' part of MOSFET (and I already know that the MOS part is obsolete). There is 'practically no input current' on the gate - you can see in this simulation that Croc Clips assumes none:

So for the most part, when we pass the voltage threshold on the gate, the MOSFET turns on. Below are some rules that I picked up on a Web site talking about the scaling effects of MOSFETs - I may have interpretted the gain part of the equations incorrectly. Even if these aren't completely accurate - they appear to be pretty decent guides based on my playing with the Crocodile Clips.

In the pictures above, I have changed the MOSFET parameters in Croc Clips to use the threshold voltage and gain factor from the data sheets for the IRF7101, IRF7303, and IRF531. The IRF7101 is used in the Roctronics circuits, so I'm using that as a baseline in the simulations. The IRF7303 is more readily available now, so we're considering it in our schematics for our implementation of the Roctronics boards. The IRF531 is available locally and in the nice TO-220 package that make bread-boarding easy. In short, it appears that our requirements are basic enough that we can use any of the MOSFETs we are looking at.

In my previous post, I wonder about the resistance from gate to source... heh, I now have a better understanding of the 'field-effect' part of MOSFET (and I already know that the MOS part is obsolete). There is 'practically no input current' on the gate - you can see in this simulation that Croc Clips assumes none:

So for the most part, when we pass the voltage threshold on the gate, the MOSFET turns on. Below are some rules that I picked up on a Web site talking about the scaling effects of MOSFETs - I may have interpretted the gain part of the equations incorrectly. Even if these aren't completely accurate - they appear to be pretty decent guides based on my playing with the Crocodile Clips.

drain-source current:

cutoff: 0 when Vg < Vt (i.e. 3.8 < 4)

linear: GainFactor * ((Vg - Vt) Vd - (Vd^2 / 2)) when 0 < Vd < Vg - Vt

saturation: (GainFactor / 2) * (Vg - Vt)^2 when 0 < Vg - Vt < Vd

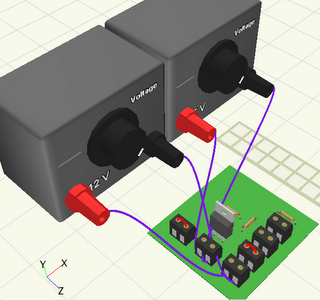

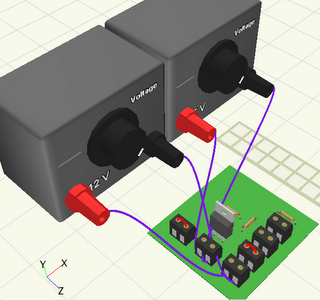

oops ... pop :( learning about MOSFETs

In books, the descriptions of MOSFETs are so simple; look at a MOSFET data sheet and it isn't quite so simple. The most big question in my mind is the drain current min - why is there a min. Does that mean that the MOSFET can support at least that specific current?

The IRF531 looked nice, so I bought a couple to learn with. I'm have a pretty basic multimeter and a limited set of resistors, so I bread-boarded some circuits with the intent of getting a most basic understanding. Here are my notes in preparation for bread-boarding and testing:

You know what's coming - after careful consideration of my constraints and building my circuit, I blew the fuse in my multimeter! I have no spares, so I'll have to finish testing tomorrow :( My mistake, besides doing this in real life rather than with Crocodile Clips, was that I didn't plan my volt versus amp metering locations. Live and learn - at least I lived...

Now that is the smart way to learn! The 3D view is pretty and neato, but what I'm not showing is the schematic with ammeter and voltmeters installed. Good stuff!

The IRF531 looked nice, so I bought a couple to learn with. I'm have a pretty basic multimeter and a limited set of resistors, so I bread-boarded some circuits with the intent of getting a most basic understanding. Here are my notes in preparation for bread-boarding and testing:

Specific Constraints

- 0-25 mA and 0-250 mA test ranges on multimeter

- 330 ohm and 470 ohm resistors are only small resistors available

- both types of small resistors are 1/2 watt resistors

Playing with MOSFET

- assuming no resistance at all on gate-source

- circuit: +5 ... 235ohm ... gate-source ... Gnd

- 21 mA used

- if resistance on gate-source, then current used will be smaller

- assuming negligable resistance (< 1ohm) on drain-source

- circuit: +12 ... 660ohm ... drain-source ... Gnd

- 18 mA used

- if 5V @ 20 mA isn't enough to turn MOSFET on, then current will be smaller

You know what's coming - after careful consideration of my constraints and building my circuit, I blew the fuse in my multimeter! I have no spares, so I'll have to finish testing tomorrow :( My mistake, besides doing this in real life rather than with Crocodile Clips, was that I didn't plan my volt versus amp metering locations. Live and learn - at least I lived...

Now that is the smart way to learn! The 3D view is pretty and neato, but what I'm not showing is the schematic with ammeter and voltmeters installed. Good stuff!

Tuesday, November 28, 2006

talking to the uMMC

I hooked up the uMMC to the PC tonight. I couldn't find an MMC or SD card around, so I just had to verify the connection and query the status of the system.

The first command I used was Z which queries the system status - the return was error code E08: Card not inserted; the other command I typed was V to request the system version and serial number - the return is kinda funny: VVV.MM SN:UMM1-NNNN-NNNN is expected, but I got 101.56 SN:UMM1-OEM - I have no serial number...

Ah well - nice to have something work. In the breadboard, I have the Vcc and Gnd on the uMMC going directly to the 5V from my power supply; the G, T, and R on the uMMC connect to the TTL Gnd, TTL Tin, and TTL Rout on the MAX232 (Sipex in this case); finally, the PC Serial has Gnd (5), Tx (3), and Rx (2) connected to the Gnd, RS-232 Rin, and RS-232 Tout. The PC serial uses 8N1 w/ no flow control @ 9600 as the default.

The first command I used was Z which queries the system status - the return was error code E08: Card not inserted; the other command I typed was V to request the system version and serial number - the return is kinda funny: VVV.MM SN:UMM1-NNNN-NNNN is expected, but I got 101.56 SN:UMM1-OEM - I have no serial number...

Ah well - nice to have something work. In the breadboard, I have the Vcc and Gnd on the uMMC going directly to the 5V from my power supply; the G, T, and R on the uMMC connect to the TTL Gnd, TTL Tin, and TTL Rout on the MAX232 (Sipex in this case); finally, the PC Serial has Gnd (5), Tx (3), and Rx (2) connected to the Gnd, RS-232 Rin, and RS-232 Tout. The PC serial uses 8N1 w/ no flow control @ 9600 as the default.

Monday, November 27, 2006

communication with AVR established!

By a bizzare turn, I happened to get communication with the AVR established - I have uploaded my program! :) Funny how things happen - I had given up on getting the AVR programmed via the parallel port and was going to try a serial method that Michael had found; I was closing out tabs in my browser and one happened to be pointing at this post about disabling the parallel port on the VMWare site. It made me suspect that my parallel port in my VM was not set for bidirectional communication, so I manually edited my VMX file to add 3 lines... and it worked!

Assuming the same old error as before, I ran uisp and got a nice little surprise!

One other great thing that I learned in this experience is that the Add / Remove Programs wizard (in Ubuntu) has an Advanced tab that allows you to select specific packages. Michael pointed out the Advanced tab and that uisp is in the package list! Good stuff.

parallel0.present = "TRUE"

parallel0.fileName = "LPT1"

parallel0.bidirectional = "TRUE"

Assuming the same old error as before, I ran uisp and got a nice little surprise!

Now - if only my code worked right :) But that is my own bug and I can fix that!

uisp -dlpt=/dev/parport0 --erase -dprog=dapa

Atmel AVR ATtiny2313 is found.

Erasing device ...

Reinitializing device

Atmel AVR ATtiny2313 is found.

uisp -dlpt=/dev/parport0 --upload if=avrledtest.hex -dno-poll -dprog=dapa -v=3 --hash=32

Reset inactive time (t_reset) 1000 us

AVR Direct Parallel Access succeeded after 0 retries.

Vendor Code: 0x1e

Part Family: 0x91

Part Number: 0x0a

Atmel AVR ATtiny2313 is found.

Page Write Disabled

FLASH Write Delay (t_wd_flash): 11111 us

EEPROM Write Delay (t_wd_eeprom): 11111 us

Uploading: flash

#####

(total 138 bytes transferred in 1.71 s (81 bytes/s)

One other great thing that I learned in this experience is that the Add / Remove Programs wizard (in Ubuntu) has an Advanced tab that allows you to select specific packages. Michael pointed out the Advanced tab and that uisp is in the package list! Good stuff.

Tuesday, November 21, 2006

mission failure - how to load AVR

I had the simple task of loading my program onto the AVR tonight to see it execute my own code for the first time; I should have suspected there was no hope. The task was too simple.

I found that I didn't have uisp loaded on Ubuntu already - no worries, I thought. I'll just build it... './configure --prefix=/usr/local/avr'. Boom - g++ not available on the Ubuntu install that I'm using. I checked the Applications - Add / Remove and I don't see it, but it must be added through some other process. So I resorted to my backup plan - install avrdude. No joy there, either: don't have yacc installed.

Back in the day when the whole system was compiled and you knew what was on it, installing g++ or yacc was a no-brainer. It is probably still a no-brainer, but ... all I want to do is load my program onto the AVR - why am I installing a new compiler or compiler compiler?! *sigh* Tired from Linux rot.

I found that I didn't have uisp loaded on Ubuntu already - no worries, I thought. I'll just build it... './configure --prefix=/usr/local/avr'. Boom - g++ not available on the Ubuntu install that I'm using. I checked the Applications - Add / Remove and I don't see it, but it must be added through some other process. So I resorted to my backup plan - install avrdude. No joy there, either: don't have yacc installed.

Back in the day when the whole system was compiled and you knew what was on it, installing g++ or yacc was a no-brainer. It is probably still a no-brainer, but ... all I want to do is load my program onto the AVR - why am I installing a new compiler or compiler compiler?! *sigh* Tired from Linux rot.

Subscribe to:

Posts (Atom)